Transparency in the hemp industry isn’t just a practice; it’s a necessity. For licensed businesses sourcing cannabinoids, understanding the journey of THCA flower from cultivation to finished product is pivotal for both compliance and consumer trust. As the market expands and regulations tighten, knowledge of the THCA flower production process does more than fulfill curiosity; it ensures businesses choose partners committed to quality, transparency, and regulatory alignment.

At The PPLs Plug, we know the importance of connecting licensed buyers with certified, lab-tested THCA flower vendors. Our B2B wholesale marketplace operates with complete COA transparency, compliance safeguards, and age verification, supporting a network that values operational efficiency and integrity. Whether you’re strategizing your next move in the hemp space or refining your sourcing standards, a clear grasp of how THCA flower is made empowers growth within a robust, community-driven ecosystem.

In this blog, we will explore the step-by-step process of producing THCA flower, from genetic selection and cultivation through post-harvest handling, preservation, and documentation practices that support compliant wholesale sourcing.

THCA flower has become an essential product category for buyers operating within regulated hemp and cannabinoid markets. Understanding how it is defined, documented, and positioned helps businesses source confidently while staying aligned with compliance and operational expectations.

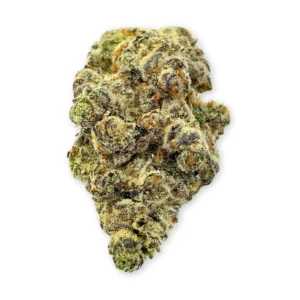

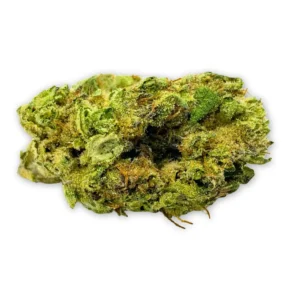

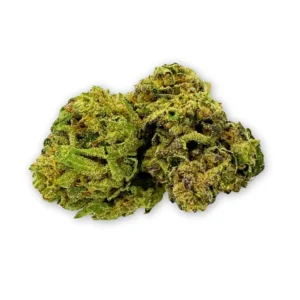

THCA flower refers to raw hemp or cannabis flower that contains elevated levels of tetrahydrocannabinolic acid before heat exposure. In its natural state, THCA exists without conversion, making cultivation methods, harvest timing, and handling practices essential to maintaining its documented cannabinoid profile.

THCA differs from Delta-9 THC in structure and behavior before decarboxylation. Exposure to heat or prolonged environmental stress can convert THCA into THC, which is why careful storage and transport are critical. Buyers rely on consistent handling practices to ensure delivered products align with lab-tested specifications.

From a regulatory standpoint, THCA flower is often evaluated based on Delta-9 THC thresholds rather than total cannabinoid content. When supported by proper testing, this allows buyers to source flower that fits within federally defined hemp guidelines while meeting internal compliance standards. Documentation accuracy is central to this process.

Certificates of Analysis play a crucial role in sourcing THCA flower. Buyers use COAs to verify cannabinoid concentrations, batch identity, and testing timelines. Reliable lab documentation helps businesses manage audits, maintain transparency, and reduce risk when distributing or processing further.

For distributors, processors, and licensed retailers, THCA flower provides flexibility in product planning and supply chain integration. Its characteristics allow buyers to support multiple downstream applications while maintaining control over documentation and inventory movement.

Because THCA flower requires careful production and handling, buyers prioritize suppliers who demonstrate consistency across batches. Reviewing past COAs, storage practices, and fulfillment reliability helps ensure long-term sourcing stability and reduces operational disruptions.

Cultivating THCA flower for wholesale markets requires precise attention to genetics, environmental control, and compliance. The production process strikes a balance between scientific rigor and agricultural expertise, ensuring that only high-quality, lab-tested flowers enter the market.

To meet regulatory requirements, harvested flower batches are segregated and sampled for laboratory testing. Results confirm the presence of THCA levels, the absence of contaminants, and the overall integrity of the cannabinoid profile before products reach the marketplace, ensuring compliance and safety for downstream buyers.

After harvest, THCA flower enters a critical phase where handling decisions directly affect stability, documentation accuracy, and wholesale readiness. Post-harvest processes are designed to manage moisture, protect cannabinoid composition, and prepare the flower for compliant storage and distribution.

Drying begins immediately after harvest to reduce excess moisture that could compromise product integrity. Flower is typically suspended or rack-dried in controlled environments where temperature and humidity are closely monitored. This gradual moisture reduction helps limit microbial risk while supporting even dehydration across each batch.

Consistent airflow, moderate temperatures, and balanced humidity levels are maintained throughout the drying period. Sudden changes in conditions can lead to uneven drying or structural issues. Controlled environments allow flowers to dry predictably while preserving documented cannabinoid characteristics.

Once target moisture levels are reached, the flower moves into the curing phase. This transition is carefully timed to prevent overdrying while allowing internal moisture to redistribute. Proper timing supports uniform texture and prepares the flower for longer-term stabilization.

During curing, the flower is stored in sealed containers and monitored regularly to ensure optimal conditions. Periodic ventilation allows remaining moisture to escape gradually. This controlled process helps stabilize the flower and maintain consistency between physical characteristics and lab-tested cannabinoid results.

After curing is complete, preservation techniques focus on protecting the flower from environmental exposure. Light-resistant storage, temperature regulation, and reduced oxygen contact help prevent degradation during warehousing and transport. These methods support product stability throughout wholesale handling.

Post-harvest handling is closely tied to lab testing and COA accuracy. Consistent drying, curing, and preservation help ensure that the tested batches accurately reflect the delivered inventory. This alignment supports traceability and reduces discrepancies during compliance reviews.

Not all products labeled as THCA flower are produced the same way. For wholesale buyers, understanding how naturally grown THCA flower differs from infused or sprayed alternatives is crucial for ensuring sourcing consistency, accurate documentation, and regulatory alignment.

Authentic THCA flower is cultivated from hemp or cannabis genetics selected to express higher levels of tetrahydrocannabinolic acid naturally. Growers rely on controlled cultivation, harvest timing, and post-harvest handling to preserve the plant’s native cannabinoid profile. The resulting flower reflects what the plant produces naturally, rather than what is added later.

Natural THCA flower development depends on genetics, environmental management, and curing techniques. Drying and curing are carefully managed to protect cannabinoid stability and ensure the flower maintains its documented composition. Each batch is trimmed and prepared without the addition of external cannabinoid materials.

Infused or sprayed products typically begin with lower-THCA hemp flower or biomass. After harvest, extracted cannabinoids, such as isolates or distillates, are applied to the flower through spraying or infusion methods. This process increases cannabinoid concentration through external application rather than plant expression.

One key distinction lies in consistency. Naturally grown THCA flower tends to show uniform cannabinoid distribution throughout the bud. Infused products may display uneven concentrations, as applied cannabinoids can settle unevenly across the flower surface or interior structures.

Naturally occurring THCA in flowers often aligns more closely with compliance frameworks that emphasize the expression of plant-derived cannabinoids, as it is a precursor to THC. Infused products may be subject to additional review or alternative classification, depending on the jurisdiction, which underscores the importance of supplier transparency.

Understanding how THCA flower is produced helps buyers manage compliance risk and product consistency. Clear sourcing information and accurate lab documentation support informed purchasing decisions and smoother wholesale operations.

Preserving THCA before decarboxylation requires disciplined control across harvesting, handling, storage, and testing. Each step is designed to protect cannabinoid composition and maintain alignment with documentation and compliance requirements.

Careful preservation practices help ensure THCA flower reaches buyers with a stable composition and reliable documentation. Consistency across handling, storage, and testing supports traceability and confidence throughout regulated supply chains.

Understanding how THCA flower is produced is crucial for licensed businesses seeking reliable and transparent sourcing within the hemp industry. Each stage, from cultivation and harvesting to lab testing and compliance verification, serves a specific purpose, ensuring the final product meets strict regulatory and quality benchmarks. At The PPLs Plug, for B2B wholesale buyers, partnering with us streamlines not only procurement but also risk management by emphasizing complete COA transparency and connecting buyers only with vendors who meet the highest standards.

The journey of THCA flower from seed to shipment is more than a technical process; it’s a community-driven effort supported by businesses, cultivators, and compliance professionals working together in an evolving legal landscape. By prioritizing lab testing and holding all parties accountable, our marketplace fosters an environment of trust that extends to every transaction. This level of dedication empowers companies to focus on growth, innovation, and delivering quality cannabinoid products to their customers.

THCA flower refers to hemp-derived buds bred to contain elevated levels of tetrahydrocannabinolic acid, documented through lab testing and produced to meet wholesale sourcing and compliance standards.

THCA flower is cultivated and handled to preserve higher THCA levels, while regular cannabis flower may contain more converted THC due to genetics, harvest timing, or post-harvest processing.

THCA flower production involves selecting suitable genetics, controlled cultivation, precise harvest timing, careful drying and curing, and storage practices designed to maintain documented cannabinoid composition.

Producers often use genetically selected strains for consistent THCA expression, verified through repeated testing, with strain choices varying by cultivator based on stability, structure, and wholesale performance.

High-THCA strains are developed through selective breeding and phenotype evaluation, where plants are tested across multiple cycles to stabilize cannabinoid profiles suitable for wholesale production.

THCA is naturally produced within the plant during flower development and is preserved through cultivation and handling practices rather than created through extraction during flower production.

The first step involves sourcing verified seeds or clones with documented THCA expression and ensuring all starting material aligns with licensing, testing, and traceability requirements.

Harvest timing and controlled handling help preserve THCA levels, as excessive heat or light exposure during harvesting, drying, or storage can alter the flower’s documented cannabinoid composition.

Sources: